by Woodsbum

It has been several months of me procrastinating, but I finally got motivated for long enough period to finish my friend’s knife sheath. Believe me when I say that it was not an easy feat. We are in the middle of the rainy season and I still have a lot of new Netflix series unwatched, not to mention some Captain Morgan Reserve that isn’t going to drink itself.

Lack of motivation and inebriation opportunities aside, I did get the sheath finished. For this build I did a few things differently. Instead of making a complete leather liner I cut out the plastic from the original sheath and then used leather for the top portion to make it snug. The first attempt didn’t work as well as I had anticipated so I ended up having to take it all apart and trim the thickness of the liner. Interestingly enough, the inner liner didn’t have to be stitched once I had the old one wet formed and waxed a little. It really holds its shape well.

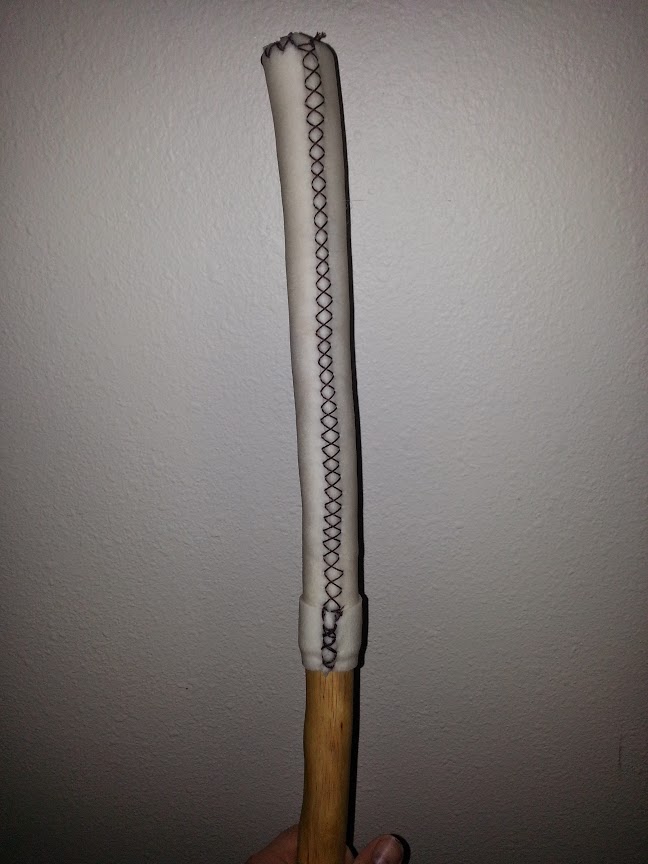

Rawhide Mora Sheath

In future builds I might do something similar from now on. If I take the leather I am building the liner out of and wet it, form it, and bind it to keep it in shape, and then wax it when it is done I can easily just use rawhide over the top as an exoskeleton of sorts. This keeps the rawhide smooth and allows it all to stay tight without the liner binding up on me after the rawhide constricts during drying.

You can see how I forced the over layer to constrict and thus hold onto the main sheath by shear friction.

Side View – Notice the forced shrinkage.

A few things that I have discovered about rawhide:

- You can adjust the shrinkage of the rawhide with use of a heat gun. If you want it to constrict tighter just dry the wet rawhide with the old Warner.

- Dying it is almost impossible, but getting it to soak up color while it is getting ready for working gives it a nice even color. I used coffee on this build but I am thinking about using some fruit juices and wine for some added shades on my next builds. I think some red wine in coffee would give an almost mahogany color.

- The more rugged the rawhide looks the better the finished product. I like how the inner part of the rawhide is textured. It gives a very interesting and rustic look to the sheath.

- Layers of different rawhide cuts and textures also gives it an interesting look.

I am thinking about doing something out of rawhide for my Marlin 1895 to hold a few additional rounds. I think I can do a rawhide cover with leather liner that will lace up one side and hold 8 to 10 cartridges. If I do, I will try and take more pictures of the actual build process. These last couple knife sheaths were fairly basic so a final description seemed to suffice.

As I do more projects and find soaks that will color stain the rawhide in interesting manners, I will update you. I will also do a few builds that have more pictures of the process. If you have been reading my site very much at all you know I am very bad about taking pictures. Someday this may change, but if you have any questions I can try and answer them for you here.

Thanks for looking and if you get a chance, try out some projects yourself.