I picked up an Elzetta Tactical Flashlight Mount for my Mossberg 590 last week since I heard great things about the company. The mount is very solid and holds my flashlight in a death grip. There is no way that the flashlight is going to come off the gun short of taking a hammer to it. I also added a Mossberg Speed Feed stock and a Tac Star Side Saddle to the gun. I wanted to get everything ready for a tactical shotgun course I’m taking in three weeks. I’ll have more about the training and the gear that I brought to it after the course is completed. In the mean time here are a bunch of pics of the gun and the accessories. As a side note I greased all the internal parts with white lithium grease and the gun action is as smooth as silk.

Tag Archives: Mossberg 590

Magpul Stock Spacer Sling Stud Install – Mossberg

by Woodsbum

I was lazy and only got out two posts for last week. I think today’s post might make up for it. GunGuy has a Mossberg 590 that he put a Magpul forgrip and stock on. The problem is that the spacers don’t have enough “meat” in the plastic to allow for installing a sling stud for hooking up a sling. That is where I was “invoked” (yes, I used the word ‘invoked’ for it is not often that someone gets the chance to use such an AWESOME word).

Here is the piece that I am talking about.

Step 1:

Mix your rum with your RC to begin the process. No project is truly kicked off until your beverage of choice is within arms reach.

Mixed with:

Step 2:

I found the correct size bit and drilled the initial hole for the stud. Now remember that the hole you drill will end up only making a channel in the “guts” of the plastic. If you look closely, you can see how the bit goes through the top part, but the plastic isn’t solid internally. It is hollowed out to save on weight, money, costs, or because “plastic trees” are endangered. At any rate, you really have to make sure that the spacer is held firmly while you drill so that it doesn’t move sideways and mess up your hole.

Drilling hole

Step 3:

Once you get the main hole drilled, you need to drill out the channel for the screw and a couple of other holes for your epoxy to set in. This will keep your epoxy from popping out of the hole as if you were only making a casting of the inside of the spacer. Look closely and you will see a hole on both sides as well as few additional channels I carved to give the epoxy some good footing.

Channels Dremel tooled out

I then installed the stud so that the threads tapped the plastic piece. I also pushed down really hard on the stud’s threads that were showing as it went into the spacer so that the channel I carved with my Dremel was actually threaded as well. Here is a picture of it all lined up and ready for the next step.

Ready for epoxy

Step 5:

At this point I plugged the holes that I had drilled so that the epoxy would not run out and drip onto my work area. I also wanted to make sure that it was well contained within those holes that I had drilled for added strength.

Holes plugged

In deciding upon an epoxy for this project, I looked at several. I even tested several. For whatever scientific reason, JB Weld was the best choice. It didn’t adhere to the plastic as well as other choices, but it really stuck to the threads of all my testing materials I worked with. It came down to a compromise of metal adherence versus plastic adhesion. To help with the plastic adhesion, I drilled those holes and forced the epoxy into those holes to work as a sort of pin. My other thoughts were to drill around the screw and use tie wire to essentially redneck it into staying, then epoxy it. I was afraid that this method would compromise the integrity of the plastic spacer too much and opted to use this method instead.

Epoxy time

I used finishing nails to force the epoxy into the holes and channels that I had carved into the plastic with a Dremel tool. After an hour, I did go in and remove the putty I used on the back side of the stud so that I could check the penetration I got with the epoxy. It filled the hole well and seemed to be setting up as expected. Here it is after an hour of drying in my garage. I told GunGuy to wait for a couple days before he installs it and tries it out, just in case the epoxy somehow was slow drying due to its age. I really think it will be fine as of tonight, but don’t tell him that.

Finished and drying

The rest of this project involved a couple more glasses of Capt and RC, a horrible movie that I can’t even remember now, and some pizza from Papa Johns. Other than that, I think this project is a wrap!

Mossberg 590 Velcro Side Saddle / Shot Shell Tray How To

by GunGuy

I’m a big fan of Mossberg shotguns. I’ve owned several over the last twenty years except for a brief stint with the Remington 870’s. I’ve apologized for my cheating ways and now I’m back in the loving embrace of a Mossberg.

I added a Velcro HSGI shotshell tray to a used Mossberg 590 that I picked up recently. Here are some notes and pictures to get you on your way to duplicating this project.

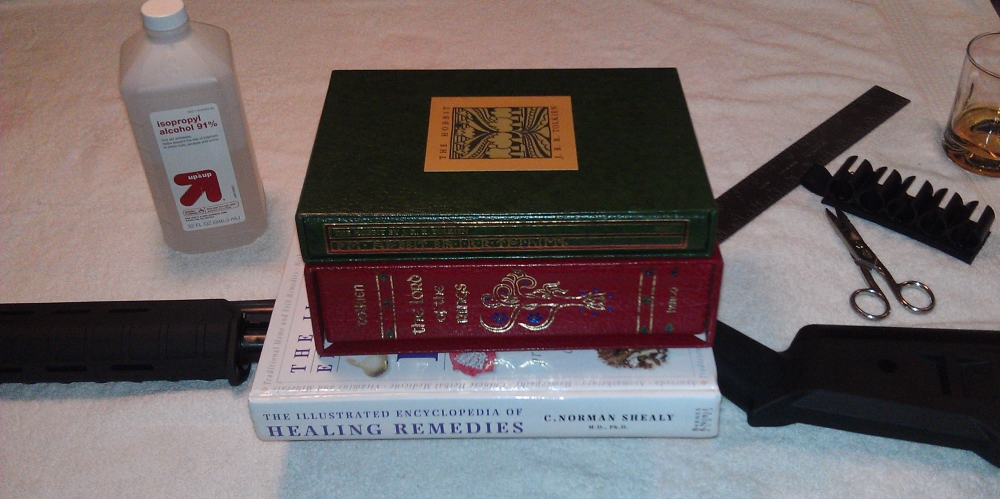

Supplies Needed

- Shotgun

- HSGI shotshell carrier

- Industrial Strength Velcro

- 91% Isopropyl Alcohol

- Scissors

- Ruler

- Utility knife

- Bunch of books to weigh down the velcro

Step 1: I prepped the side of the shotgun by wiping it down with Isopropyl alcohol several times and then let it dry.

Step 2: Using the ruler and utility knife I cut the Velcro a little longer than the shot shell carrier and a little shorter then the height of the side of the receiver. The size of the Velcro strip was 5 .25 inches wide and 1.5 inches high. I used scissors to round the corners so they would not curl up.

Step 3: Carefully I placed the Velcro just in front of the trigger group pins so I could have access to them when field stripping and also allow the serial number to be seen. The adhesive is very tacky so and it won’t come up once you put it down on the gun.

Step 4: I stacked several books on top of the newly laid piece of Velcro and let it sit for 24 hours until it cured.

Step 5: Once the adhesive cured I put the shot shell carrier on the shotgun and gave it a test run by pulling it off and putting it on several times. I have a shotgun class coming up shortly and I’ll give it a thorough breaking in then.